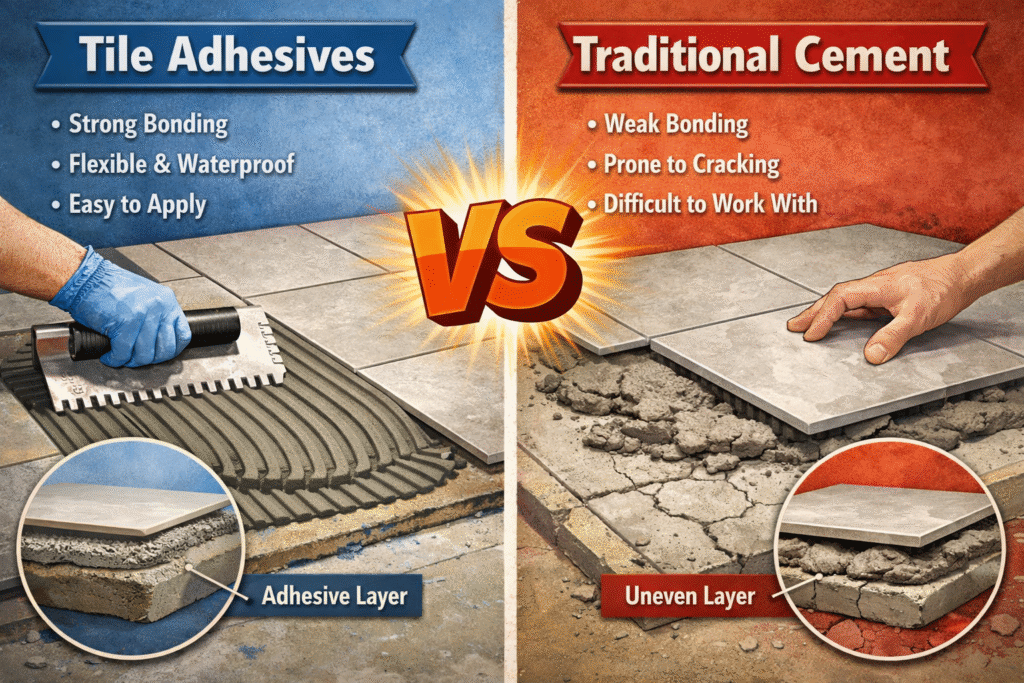

For many years, traditional cement slurry was the default choice for fixing tiles in Indian construction. However, the arrival of modern technologies in construction has made tile adhesives the most preferred solution in all residential, commercial, and industrial projects. As a construction chemicals expert, the difference in performance, durability, and efficiency between the two is clear.Tile adhesives are not just a new trend they are engineered products designed to address the limitations of cement while meeting the demands of today’s advanced tile types such as vitrified tiles, porcelain slabs, heavy stone, and large-format tiles.

1. Adhesion Strength: Where Cement Fails and Adhesives Win

Traditional cement offers only mechanical bonding. This means:

It requires a perfectly prepared surface

- It requires a perfectly prepared surface

- It tends to crack when subjected to movement.

- It loses strength due to incorrect water ratios

- Tiles often debond over time

Tile adhesives, on the other hand, provide chemical and mechanical bonding. With added polymers, binders, and graded fillers, they firmly grip the tile and substrate even under stress, temperature change, or vibration.

This ensures long-term durability and reduces complaints such as tile popping, hollow sounds, or edge lifting.

2. Compatibility With Modern Tiles

It used to be that when tile varieties were limited, cement was suitable. Today’s tiles are denser and less porous, with larger sizes, hence making cement unsuitable because it could not make a strong enough bond.

Tile adhesives are formulated for:

- Porcelain tiles

- Vitrified tiles

- Large-format slabs

- Natural stone

- Glass mosaic

- Exterior cladding tiles

Whether the surface is concrete, plaster, old tiles, or even plywood-with special grade adhesives, the tile adhesive will be strongly and flexibly bonded.

3. Speed, Convenience & Application Efficiency

It requires on-site mixing, addition of sand, manual proportioning, and skill. Variations in mixing often result in performance failures.

Tile adhesives solve this problem through:

Ready-mix formulation

- Controlled consistency

- Faster coverage

- Cleaner installation

- Reduced thickness (3–6 mm instead of 12–20 mm)

Save time, reduce material wastage, and achieve consistent results for the contractor.

4. Precision, Levelling & Finishing Quality

A big plus of tile adhesive is its workability. It allows for better adjustment of the tiles and provides:

- Uniform bed thickness

- Perfect levelling

- Better alignment

- Reduced lippage

Poor finishing and height variation due to unevenness of cement slurry are common, and often, it dries too fast.

5. Moisture Resistance & Long-Term Durability

Water is absorbed in the traditional cement. Due to this fact, it is prone to:

- Wetness and discoloration

- Cracking

- Debonding

- Efflorescence

There are water-retention chemicals and different polymers in tile adhesives that give them superior resistance to moisture. This makes them ideal for:

- Bathrooms

- Kitchens

- Balcony space

- Terraces

- Pools

- Exterior walls

With adhesives, tiles remain firmly bonded even in wet conditions.

6. Adhesives as Part of a Complete Construction Chemical System

Modern tile installations are not single-process tasks anymore. It involves:

- Surface treatment

- Priming

- Waterproofing

- Adhesive application

- Grouting

- Finishing

Many professionals always utilize repair materials prior to tiling to improve the substrate. For instance:

“Contractors often utilize Epoxy Resin Putty manufacturer in Gujarat products to prepare surfaces for tile laying,”

“Materials used during the renovation process for repairing walls as well as metalwork serve to strengthen the walls as well as provide a sound foundation for the installation of tiles.”

This system-based approach ensures a more durable and professional tile finish.

7. Cost Comparison: Adhesives Are More Economical Long-Term

Cement appears cheaper per kg, but the hidden costs are high:

- Rework due to tile failure

- Cracked tiles

- Hollow sounds

- Extra labour

- Increased material wastage

- Water leakage issues

Tile adhesives provide:

- Greater coverage

- Lower application thickness

- Higher durability

- Minimal wastage

- Faster completion

Over time, adhesives save money while delivering better performance.

8. Safety & Performance Standards

The tile adhesives are formulated as per international standards as follows:

- EN standards

- IS standards

- ASTM Test Methods

This ensures consistent, predictable performance. Cement mixed on site cannot match this reliability.

Conclusion:

Tile Adhesives Are the Future of Indian Construction

When comparing tile adhesives with traditional cement, the difference is clear. Tile adhesives offer superior bonding, faster application, better compatibility with modern tiles, and long-term durability. They reduce installation issues, minimize failures, and deliver a professional finish every time.

As the construction industry in India evolves, tile adhesives have become a technical necessity not just an optional upgrade. Choosing the right adhesive from a reliable construction chemicals brand ensures performance, longevity, and peace of mind.