Floors are not merely a walking surface — they support people, machinery, and daily traffic. They get worn down, dented, chemically exposed, and stained in the process. To shield them and make them look better, various coatings and paints have been developed. Among these, epoxy resin floor paint has become universally popular for its durability, looks, and long-lasting durability.

What is Epoxy Resin Floor Paint?

Epoxy resin floor paint is a two-part coating system made of an epoxy resin and a hardener. When the two are blended, a chemical reaction is triggered and a hard, plastic-like surface is created, bonding strongly to the concrete surface. This provides a smooth, seamless, and long-lasting finish.

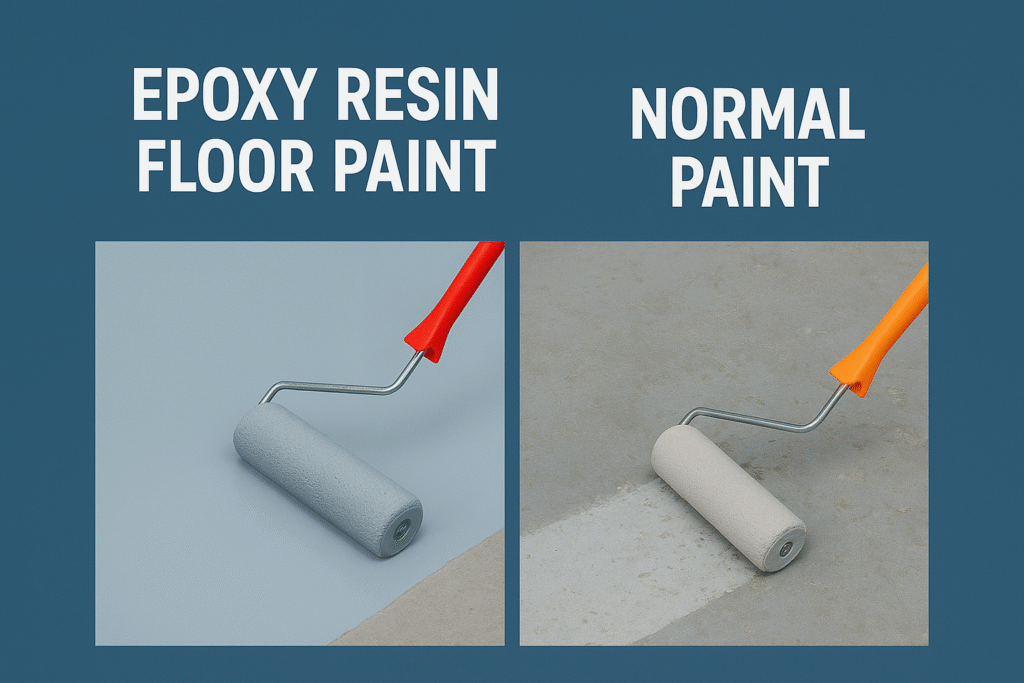

Unlike regular paints that dry by air evaporation, epoxy paint chemically cures. This curing provides it with superior hardness, adhesion, and resistance, abilities that regular paints are not capable of.

Why Epoxy Resin Floor Paint is Better Than Normal Paint

1. Exceptional Durability

Epoxy paint is made to support heavy loads, abrasion, and repeated motion. It doesn’t readily chip or peel and can withstand much more stress than other paints. This suits them for floors in workshops, garages, warehouses, and industry.

2. Superior Chemical Resistance

Whereas most paints tend to react or discolor when subjected to oils, fuels, or detergents, epoxy resin paint is resistant to numerous chemicals. Their tight, non-porous structure resists damage and staining, thus maintaining the surface beneath safely.

3. Smooth and Seamless Finish

Epoxy coatings create a continuous surface without joints or gaps. This helps in preventing dust, dirt, and bacteria buildup, making it easy to clean and maintain. Such flooring is preferred in hospitals, laboratories, and food industries where hygiene is critical.

4. Aesthetic and Glossy Appearance

Epoxy resin floor paint gives a shiny, reflective finish that strengthens the brightness of any room. It comes in a range of colors and finishes, meaning customization to match industrial, commercial, or contemporary interiors.

5. Easy Maintenance and Cleaning

Epoxy-coated floors are resistant to water, stains, and spills. Regular sweeping and mopping are typically sufficient to keep them shining. Compared to regular painted floors, which frequently require repainting or retouching as they fade or peel.

6. Long Lifespan and Cost Efficiency

Although the initial cost of epoxy floor paint can be slightly higher, it offers great value over time. Its durability and low maintenance requirements make it more economical in the long run. Many epoxy floors last for 5 to 10 years or more before needing reapplication.

Epoxy Floor Paint vs. Normal Paint – In Simple Terms

Regular floor paints are mainly for color and a short-term protection layer. They might appear good at first but tend to fade, peel, or wear out within a matter of months, particularly in areas with heavy traffic.

Epoxy resin floor paints, on the other hand, do much more than decorate. They strengthen the surface, seal the pores of the concrete, and offer resistance against impact, moisture, and chemicals. This means epoxy not only looks good but also enhances the life and performance of the floor beneath.

In short, normal paint adds color, epoxy adds strength, protection, and longevity.

Common Applications of Epoxy Resin Floor Paint

Epoxy flooring is extremely versatile and can be utilized in a wide range of industries, including:

Factories and Warehouses: To handle heavy machinery and traffic.

Garages and Workshops: To withstand oil, grease, and fuel spills.

Hospitals and Laboratories: For dust-free, clean, and hygienic conditions.

Commercial Spaces and Showrooms: To enhance aesthetics and brightness.

Parking Areas and Basements: For water resistance and durability.

This flexibility renders epoxy resin coatings both useful for operation and decorative purposes.

How Epoxy Resin Floor Paint is Applied

Surface Preparation: The surface of the concrete will have to be cleaned, dried, and patched. Oil, dust, or cracks may need to be removed for successful adhesion.

Priming: A layer of primer improves the bond between the epoxy and concrete substrate.

Mixing and Application: The hardener and resin are combined in the proper proportion and applied smoothly with the help of rollers or spreaders.

Curing: The floor must be left undisturbed for a specific period to allow the coating to cure completely. Proper curing provides the floor with its ultimate hardness as well as chemical resistance.

Important Things to Keep in Mind

- Make sure the surface is dry and free from moisture before coating.

- Mix resin and hardener in the right proportion as recommended.

- Maintain suitable temperature and humidity during application.

- For the best results, professional application is recommended, particularly for large or major areas.

Conclusion

Floor paint using epoxy resin is a contemporary solution for individuals who require strength, longevity, and beauty in their floor. It not only enhances the appearance of a space but also protects it against wear, chemicals, and moisture. Whether it’s an industrial floor, a commercial workspace, or a home garage, epoxy resin flooring offers unmatched performance and longevity, qualities that ordinary paints simply can’t match. Investing in epoxy flooring is, ultimately, an investment in durability, cleanliness, and long-term value.